Partnering with a trusted service provider for stretch wrap machine repair is a cost-effective business decision.

Partnering with a trusted service provider for stretch wrap machine repair is a cost-effective business decision.

Blog Article

Recognizing the Significance of Timely Stretch Wrap Device Repair Work Solutions

When it comes to extend cover machines, timely repair services can make all the difference. What variables should you take into consideration to ensure your makers stay in leading shape?

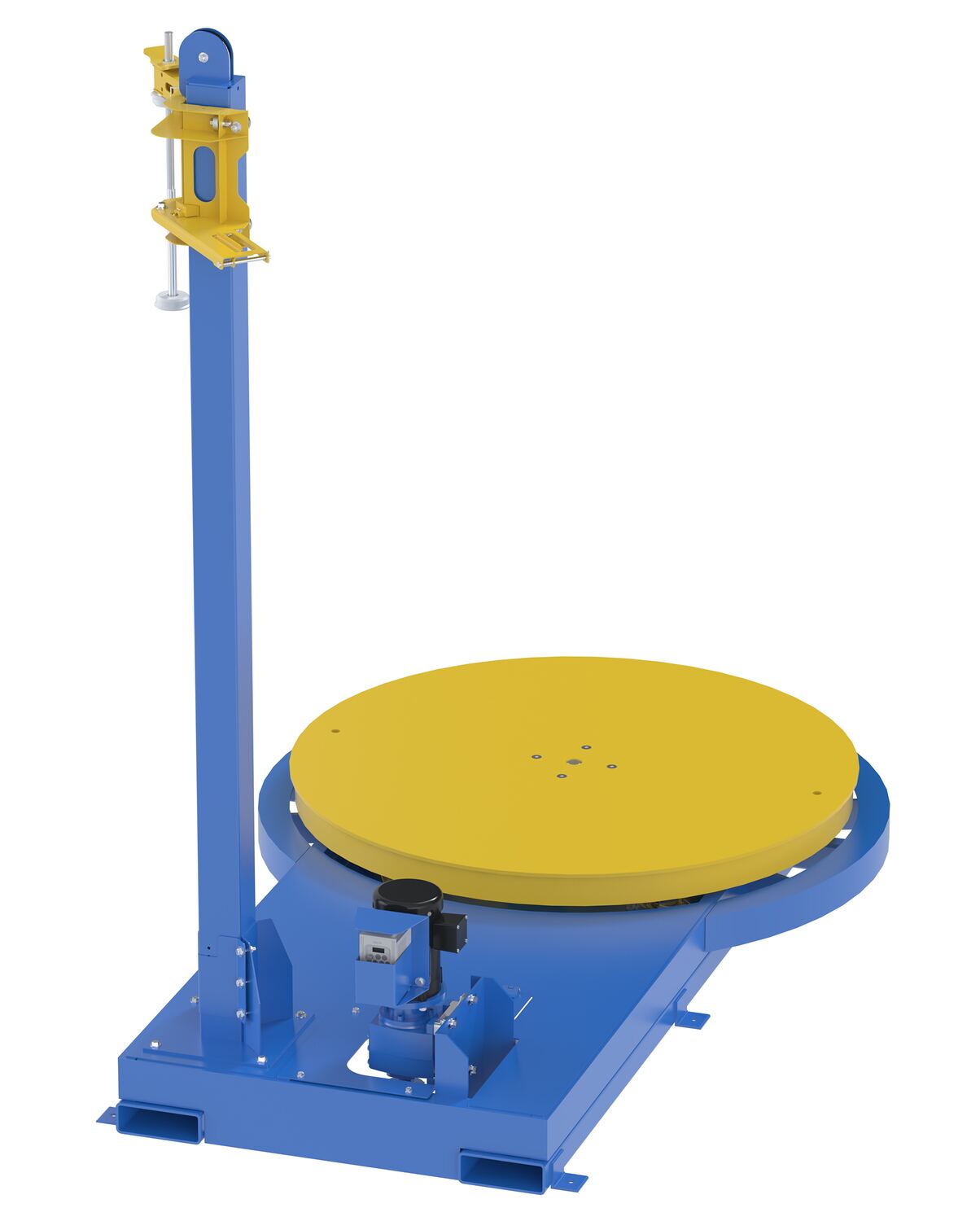

The Duty of Stretch Cover Machines in Modern Manufacturing

Stretch wrap makers play a vital role in modern-day production by guaranteeing that products are safely packaged for transport and storage space. You depend on these devices to offer stability and defense, protecting against damage throughout transit. When you use stretch wrap, you reduce the danger of items changing or getting smashed, which can bring about costly losses.

Additionally, making use of stretch cover equipments can enhance your total supply chain efficiency. By enhancing the packaging procedure, you lower labor prices and quicken delivery times, guaranteeing that your customers obtain their items without delay. In today's hectic market, this benefit is vital.

Usual Issues That Cause Device Downtime

When your stretch wrap equipment experiences downtime, it can usually be traced back to mechanical failings or driver errors. Recognizing these typical issues can aid you avoid pricey disturbances. By addressing these points, you can maintain your operations running smoothly.

Mechanical Failures and Break Downs

When parts wear down or break, your stretch wrap machine might stop unexpectedly, impacting productivity. Additionally, electrical failings can trigger breakdowns in the machine's control system, developing more hold-ups. By prioritizing prompt repair work, you're not only minimizing downtime however also expanding the lifespan of your maker.

Driver Errors and Oversights

While operators play a vital function in the smooth performance of your stretch wrap machine, their errors and oversights can bring about substantial downtime. Usual problems like inappropriate loading, wrong setups, and failure to monitor cover stress can trigger hold-ups and item damage. If an operator disregards to examine for damaged movie, it can lead to inconsistent wrapping and raised waste. Additionally, miscommunication throughout shifts can cause vital modifications being ignored. It's crucial to provide extensive training and routine refreshers to lessen these blunders. Motivating a culture of liability and alertness among your group can considerably minimize downtime. Ultimately, investing in driver training repays by boosting performance and extending your machine's lifespan.

The Financial Impact of Postponed Fixings

Delaying repair services on your stretch wrap device can lead to substantial economic consequences that surge via your whole operation. When your equipment breaks down, efficiency plummets.

In addition, prolonged delays can rise small concerns into significant problems, needing extra considerable repairs or even full substitute of the equipment. This can stress your spending plan and interfere with capital. Delays can also affect your delivery routines, harming consumer satisfaction and possibly causing you to lose company to competitors. Ultimately, prompt fixings are crucial to preserving your base line and making certain smooth procedures. Don't take too lightly the economic effect of disregarding those repair needs.

Benefits of Proactive Maintenance Programs

Timely fixings can conserve you from pricey downtime, but executing an aggressive maintenance program takes it an action further. By routinely arranging upkeep, you can recognize potential problems prior to they intensify into major problems. This not just maintains your stretch cover maker running efficiently however also prolongs its life expectancy. You'll find that constant upkeep decreases the probability of unexpected failures, permitting your operations to run extra successfully.

With fewer disruptions, your labor force can concentrate on their jobs without the anxiety of sudden device failings. Preserving peak efficiency can boost the high quality of your covered products, making certain consumer satisfaction.

Determining Indications That Your Device Needs Repair

As you operate your stretch wrap maker, it is important to remain watchful for indications that show it might require repair work. Among the first things to search for is uncommon sound. If you listen to grinding, squeaking, or any kind of various other odd audios, it might indicate an underlying problem. Additionally, look for inconsistent wrapping. If the movie isn't stuck properly or you observe uneven tension, your device could be malfunctioning.

One more sign is a boost in downtime. If your device often quits or calls for changes, it is time to investigate. Also, watch on the equipment's speed; if it's slower than normal, something could be incorrect. Any noticeable damage like frayed cable televisions or leaks ought to not be overlooked. Promptly attending to these indications can protect against much more considerable issues down the line, ensuring your operations run efficiently.

Selecting the Right Fixing Service for Your Requirements

Exactly how do you select the appropriate fixing solution for your stretch wrap maker? Look for professionals who specialize in stretch wrap machines and have a proven track document.

Following, examine their feedback time. A dependable solution ought to supply punctual assistance, as maker downtime can be expensive. It's additionally vital to recognize if they provide emergency situation fixings.

Do not fail to remember to inquire about warranties on repairs and components. A reliable service supports their job, giving you satisfaction.

Last but not least, contrast pricing yet stay clear of selecting entirely based on price. Sometimes, the cheapest option may result in substandard service. By thinking about these aspects, you'll find a repair service that meets your needs and keeps your stretch cover equipment running smoothly.

Approaches for Minimizing Stretch Cover Device Downtime

Educating your drivers is one more crucial approach. Outfit them with the expertise to recognize and resolve small problems before they cause significant malfunctions. Urge them to keep a log of any kind of abnormalities, which aids in detecting issues much faster.

Additionally, keeping a supply of vital spare components can considerably lower downtime. When something breaks, having the ideal parts accessible suggests you won't need to await shipments.

Finally, think about investing in real-time tracking systems. These systems can signal you to efficiency adjustments, allowing for instant treatment. By applying these strategies, you'll keep your stretch wrap maker running efficiently and efficiently.

Frequently Asked Concerns

Exactly How Usually Should Stretch Cover Machines Be Serviced?

You need to service stretch wrap devices on a regular basis, ideally every six months. If you observe any type of performance issues or unusual audios, don't wait-- schedule upkeep promptly to prevent costly breakdowns and ensure peak performance.

What Are the Normal Costs Connected With Stretch Wrap Device Repairs?

Regular prices for stretch cover equipment repair services vary, yet you might expect to spend in between $200 to $1,500 depending on the problem. Regular maintenance can assist reduce these expenses and prolong your device's lifespan.

Can I Carry Out Basic Upkeep on My Stretch Wrap Device?

Yes, you can perform click here basic upkeep on your stretch wrap maker. On a regular basis examine for deterioration, cleanse the elements, and guarantee correct lubrication. Keeping it in great form can expand its lifespan and improve efficiency.

Exactly how Do I Know if a Repair Service Solution Is Trusted?

To discover a trusted repair service, inspect on-line testimonials, ask for suggestions, and validate certifications. A trustworthy service will certainly offer clear estimates, service warranty alternatives, and timely communication, guaranteeing you feel great in their know-how.

What Should I Do in Situation of an Emergency Situation Equipment Breakdown?

In instance of an emergency device failure, you should promptly quit operations, assess the problem, and contact your repair solution. Keep critical contact numbers handy, and record the trouble for reliable fixing when aid arrives.

Final thought

To summarize, understanding the relevance of prompt stretch cover device repair work can considerably boost your operations. Bear in mind to stay alert for indications of wear and choose a trustworthy repair work service to maintain your equipments running smoothly.

Report this page